- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-06-24 Origin: Site

A marine valve helps control how liquids or gases move in ship pipelines. These valves are very important for things like water intake and fuel supply. Think about if a fire starts in a ship’s engine room. The crew uses marine valves to shut off fuel lines fast and stop danger. Marine valves help keep people safe, make work easier, and follow strict ship rules. New reports say there are more machine problems now, including valve troubles, when ships are working. Testing and taking care of marine valves often helps stop accidents and expensive delays.

Marine valves help control how liquids and gases move on ships. They keep ship systems safe and working well.There are many types of valves. Gate, globe, ball, butterfly, and check valves each have a special job. They help manage flow and pressure on the ship.Checking and fixing valves often stops leaks and accidents. This also saves money on repairs and keeps the ship running smoothly.Remote control systems make it easier to use valves. Crews can open or close valves from far away and stay safe.Using strong, certified valves helps ships follow safety rules. Good valves also last longer and help ships work better.

A marine valve is used to control how liquids and gases move in a ship’s pipes. Valves can start or stop the flow. They can also change how much fluid goes through. Some valves make sure fluids only go one way. Ships have many kinds of valves. These include gate, globe, ball, butterfly, and check valves. Each type is best for a certain job. Gate valves open or close all the way. This lets fluids move freely or stop. Ball valves have a ball that turns to control flow. Butterfly valves use a disc to change flow quickly. These valves help with water intake, fuel supply, and loading cargo.

Tip: Picking the right marine valve for each job helps ships work well and stay safe.

Some ways marine valves are used on ships are:

Controlling water to cool engines

Managing fuel lines for engines and generators

Handling water for firefighting

Moving wastewater and bilge water

Storing and moving liquid cargo

Marine valves are important for ship safety. They let the crew turn off fuel or water lines fast in emergencies like fires or leaks. Good marine valves lower the chance of accidents at sea. Experts say valve failures can cause big safety problems. These include harm to the environment and costly delays. Checking and fixing valves often keeps the crew and ship safe.

Valve Remote Control Systems (VRCS) are now used more on ships. These systems let the crew control valves from far away. This helps stop mistakes and makes things safer. VRCS help with ballast water, fuel, firefighting, and cooling. More ships use these systems because of strict safety rules and the need for better automation. When ships use good marine valves and take care of them, they have fewer accidents and safer trips.

Marine valves help control how fast and how much liquids and gases move in ship pipes. They keep things running at the right speed and pressure. This protects equipment and saves energy. Relief valves open by themselves if pressure gets too high. This stops damage to pipes and machines. Many marine valves are made from strong materials like stainless steel. This helps them last longer and handle tough jobs.

Here is a table that shows how marine valves help in different ship systems:

Application Area | Measured Benefits in Flow Control and Pressure Stabilization |

|---|---|

Ballast Control Systems | Exact water flow keeps the ship steady and balanced. |

Bilge Management Systems | Good seals stop leaks and keep pressure steady. |

Fuel and Oil Lines | Fire-safe valves keep flow steady and stop pressure changes. |

Cooling Circuits | Good flow control keeps engines from getting too hot. |

Firefighting Systems | Fast valves give steady water flow in emergencies. |

Hydraulic Systems | High-pressure valves keep machines working safely. |

Cryogenic Applications | Strong seals control very cold liquids safely. |

Desalination Systems | Corrosion-resistant valves keep seawater moving for freshwater. |

Marine valves also help ships save energy by keeping flow and pressure steady. They stop sudden changes that could break equipment or cause leaks. By using the right valves, ships work better and avoid expensive repairs.

Gate valves use a flat or wedge-shaped gate to start or stop flow. These valves work best when fully open or fully closed. Shipbuilders pick gate valves because they seal well and handle high pressure. Gate valves are strong and do not rust easily. Many gate valves from top brands have special certificates. These show the valves meet tough marine rules. How long a gate valve lasts depends on its material, design, and care. Some gate valves use flexible or solid wedges to seal better and last longer in rough sea conditions.

Globe valves control flow by moving a disc up or down. This lets crews adjust flow very carefully and keep pressure steady. Bronze globe valves do not rust, so they are good for seawater. These valves can handle high pressure and heat. This is important for many ship systems. Globe valves are easy to fix and work well for a long time. They often meet quality standards to make sure they work right.

Globe valves give:

Careful flow control

Strong protection from rust

Long life with little fixing needed

Ball valves use a ball with a hole to let liquid pass or stop it. Turning the ball opens or closes the path. These valves are liked because they work fast and seal tightly. Ball valves have certificates that show they are safe and good quality. They work well in systems with high pressure and heat. Ball valves also leak very little, which keeps ship systems safe and working well.

Ball valves have:

Quick use

Tight sealing

Many safety certificates

Butterfly valves use a spinning disc to control flow. These valves are light and simple to put in place. New butterfly valves are made to save energy and keep pressure steady. Shipbuilders use them in cooling, ballast, and fuel systems. Butterfly valves last longer and cost less to fix now. Computer designs help make these valves stronger and better, even if the ship shakes.

Note: Butterfly valves help ships use less energy and have fewer stops.

Check valves, also called non-return valves, let liquid move in just one way. These valves stop liquid from going backward, which protects pumps and other parts. There are different types like swing, lift, and ball check. Non-return valves are important for bilge, ballast, and fuel systems. Check valves need little care and work by themselves, so they help keep ships safe.

Safety and relief valves keep ship systems safe from too much pressure. These valves open if pressure gets too high and let out liquid to stop damage. Ships use them in steam, fuel, and hydraulic systems. Safety and relief valves must follow strict rules and have special certificates. Quick-closing and cryogenic valves are also used for special jobs like LNG and methanol.

UNIVALVE makes many kinds of marine valves, like high and low pressure, cryogenic, and quick-closing types. Their valves meet world standards and have many certificates. This helps keep ships safe and working well today.

Marine valves use different ways to control how fluids move. Each type of valve has its own job. Some valves stop flow all the way. Others let the crew change how much liquid or gas goes through.

Gate valves shut off flow tightly.

Globe valves let you control flow carefully.

Ball and butterfly valves open and close fast.

Check valves stop fluids from going backward.

Safety valves let out pressure to protect parts.

Valves help keep ship systems safe by sealing well and controlling pressure. Good seals stop leaks and keep fluids in the right place. Tests show that using valves a lot can wear out seals and cause leaks. Strong materials and smart design help valves last longer, even in hard sea conditions.

Crews can use their hands or remote systems to work marine valves. Manual valves have wheels, levers, or handles. These let the crew open or close valves right at the spot. Remote-controlled valves use electric, air, or hydraulic power. These let the crew control valves from far away, like in a control room.

Motorized butterfly valves use electric motors to spin the disc inside. This lets the crew control flow quickly and exactly. Automation helps ships react fast to changes and makes things safer. Remote systems also help stop mistakes during emergencies.

Tip: Remote control systems help crews handle many valves at once, which is useful on big or complicated ships.

Marine valves need to work in tough sea conditions. Makers use strong stuff like stainless steel, cast iron, bronze, and special alloys. These materials fight rust, corrosion, and high pressure. Some valves work in very cold places, like in LNG or methanol systems.

A table below shows common materials and what they are used for:

Material | Key Properties | Typical Use |

|---|---|---|

Stainless Steel | Fights rust, very strong | Seawater, fuel, chemicals |

Cast Iron | Tough, not expensive | Water, low-pressure lines |

Bronze | Does not rust, strong | Seawater, cooling systems |

Special Alloys | Handles heat and pressure | LNG, cryogenic systems |

Good building and regular care keep valves working well. Using quality materials and smart design helps marine valves stay strong, even when used a lot.

Marine valves are very important for ships. They help ships run safely and smoothly. When strong pumps work with good valves, ships break down less. This also means ships make less CO2. Smart control systems can change how much cooling water is used. They can save up to 90% energy by adjusting to seawater temperature. Using machines to control valves helps stop mistakes. It also lets crews act faster and control fluids better. If a marine engineer can watch valves in real time, they can find problems early. This means there are fewer surprises or failures. Shutting off important systems quickly during trouble keeps the ship safe.

Marine valves with sensors and controllers help engineers save energy and make ships work better.

Ships must follow strict rules to use marine valves. These rules come from big groups around the world. The table below shows how these groups check for safety and quality:

Certification Body | Role in Compliance | Compliance Details |

|---|---|---|

CCS | Inspections, testing, audits | Meets technical and quality needs for marine use |

ABS | Safety and reliability checks | Proves valves work well in harsh conditions |

LR | Audits and testing | Follows global maritime rules and safety standards |

NK | Certification and inspection | Checks durability and system integrity |

BV | Quality assurance | Meets tough technical standards |

KR | Inspection and certification | Confirms safety and performance |

RS | Certification and audits | Validates reliability and corrosion resistance |

DNVGL | Inspections and testing | Certifies safety and operational integrity |

These certificates show that marine valves are safe and high quality.

Taking care of marine valves helps ships work better and longer. A marine engineer should clean heat exchangers and keep water moving well. This can make the system work up to 30% better. Using smart tools to watch valves can stop 20% of failures. Checking and cleaning valves often stops rust and dirt. This means fewer problems and less time fixing things.

Tips for best results:

Check valves often for leaks or damage.

Use digital tools to watch how valves work.

Change old parts before they break.

Follow the maker’s plan for care.

A marine engineer who does these things helps the ship avoid big repairs. This keeps everyone safe. Valves that get regular care last longer and work better. This makes them a good choice for any ship.

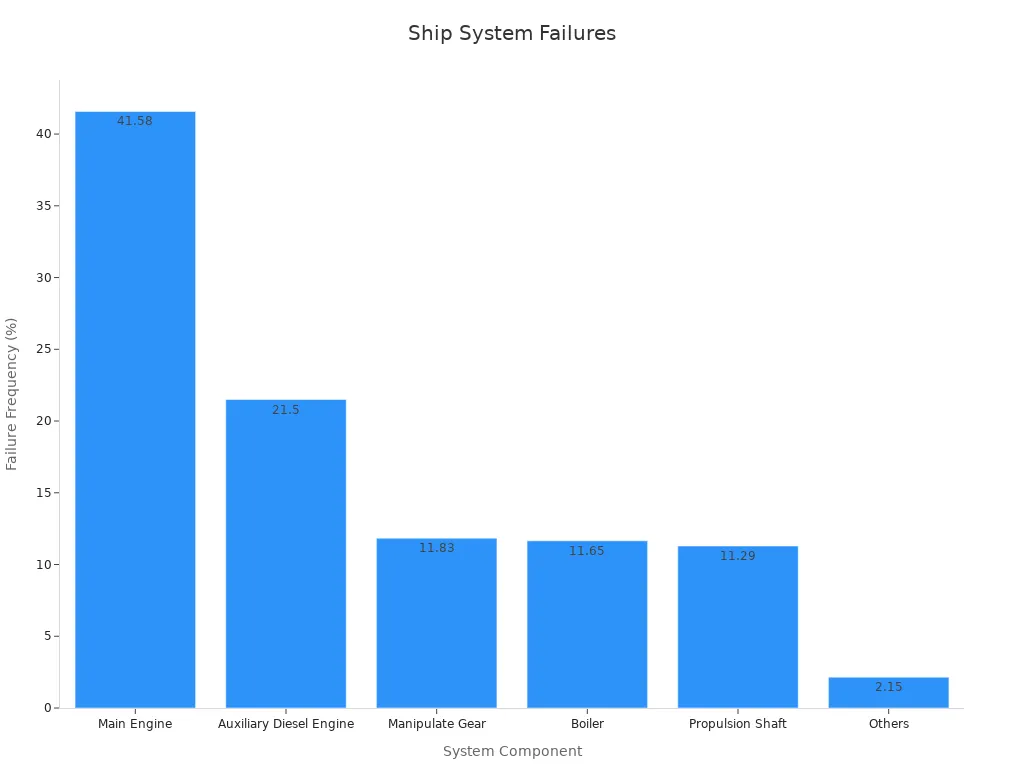

Marine valves keep ships safe and running well. Choosing the right valve and checking it often helps avoid big problems. Valve failures in main engines cause over 40% of ship system issues.

To keep valves working their best, crews should:

Follow clear manuals and use certified parts.

Track valve use and plan checks based on real data.

Pick valves with trusted certificates like LR, ABS, or DNV/GL.

Smart care and quality choices help ships stay safe and efficient.

A marine valve helps control how liquids or gases move in ship pipes. It can turn the flow on or off. It can also change how much liquid or gas moves. This keeps ship systems safe and working well.

Crews need to check marine valves often. Most experts say to check them during normal ship care. This helps crews find leaks, rust, or damage early.

Marine valves need certificates to show they follow safety and quality rules. Groups like LR, ABS, or DNV/GL give these certificates. This proves the valves work well on ships.

Yes. Some marine valves, called cryogenic valves, can handle very cold liquids like LNG or methanol. These valves use special materials to stay strong in cold places.

If a marine valve fails, it can cause leaks or pressure loss. It can also make systems break down. This can lead to safety problems, pollution, or costly repairs. Checking valves often helps stop these problems.