- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-06-26 Origin: Site

The best marine ball valves for 2025 come from UNIVALVE, Watts, Cepex, Forespar Marelon, Apollo, and Philmac. Each brand has its own special features. UNIVALVE has new designs and worldwide certifications. Watts is great because it uses bronze and is very reliable. Cepex is easy to take care of with its Tru-Union design. Forespar Marelon is best for stopping rust and is very light. Apollo is famous for strong stainless steel choices. These options are important. Marine places need valves that do not rust, work well under pressure, and follow strict rules.

Ball valves now have smart technology. This lets people check them in real time. It makes marine systems safer and work better. Their market share should reach 25.4% in 2025. This is because they last long and keep people safe in tough places.

Material Type | Temperature Range (°C) | Max Pressure (bar) | Corrosion Resistance & Durability Highlights |

|---|---|---|---|

Stainless Steel (316) | Up to 220 | 70 | Very good at stopping rust because of special layers; great for marine use; lasts a long time. |

Brass | Up to 160 | 55 | Lasts long in safe liquids; not good for salty water unless special brass is used. |

PVC | Up to 60 | 16 | Stops rust in chlorinated water; light; good for low pressure; cannot handle high heat. |

Carbon Steel | Up to 180 | 40 | Strong and can take heat; rusts more easily so needs a cover; lasts long but needs care. |

Cast Iron | Up to 120 | 40 | Lasts long with a cover; can break and rusts more; not good in salty water. |

Bronze | N/A | N/A | Does not crack; stops rust well; costs less money. |

Chrome | N/A | N/A | Stops wear; has tiny holes and can rust in seawater. |

Titanium | N/A | N/A | Very good at stopping rust and scratches; best for strong acids; lasts the longest. |

Picking the right marine ball valve keeps things safe and working well. It also helps follow the rules in every marine job. You will see more detailed reviews and expert advice in the next parts.

Pick marine ball valves made from stainless steel, bronze, or Marelon. These materials stop rust and last a long time. - Check if the valves have certifications like API, ISO, and Lloyd’s Register. These show the valves are safe and good quality. - Choose the right valve size and material for your boat. Think about pressure, temperature, and water type. - Check and take care of valves often. Use smart sensors if you can. This helps stop leaks and makes valves last longer. - Buy good ball valves because they seal well and stop water fast. This also saves money on repairs later.

You need to think about a few things when picking a marine ball valve. The table below shows top brands and models. It looks at what they are made of, how much pressure they can take, what certifications they have, and how much they cost. These things help people find the best valve for their boat or ship.

Brand/Model | Material | Max Pressure (bar) | Certifications (Sample) | Price Range ($) |

|---|---|---|---|---|

UNIVALVE | Stainless Steel, Bronze, Special Alloys | 10–100 | LR, ABS, DNV/GL, BV, CCS | 80–350 |

Watts Marine Bronze | Bronze | 55 | UL, FM, ISO | 60–180 |

Cepex Tru-Union | PVC, Polypropylene | 16 | ISO, WRAS | 30–90 |

Forespar Marelon | Marelon Composite | 10 | ABYC, ISO | 70–200 |

Apollo Marine | Stainless Steel | 70 | API 607, ISO | 100–400 |

Philmac | Polypropylene | 16 | ISO, WRAS | 25–80 |

Note: Certifications like API 6D and API 607 mean the valves go through tough tests. API 6D checks if the valve works well and is strong. API 607 makes sure the valve is safe in fires. These rules are very important for boats because safety matters a lot.

Each marine ball valve has something special. UNIVALVE uses many materials and has lots of certifications. This makes it good for tough jobs on the water. Watts uses bronze, which does not rust and can handle medium pressure. Cepex has a Tru-Union design, so it is easy to fix and put in. Forespar Marelon is light and does not rust in saltwater. Apollo has strong stainless steel valves that work with high pressure and heat.

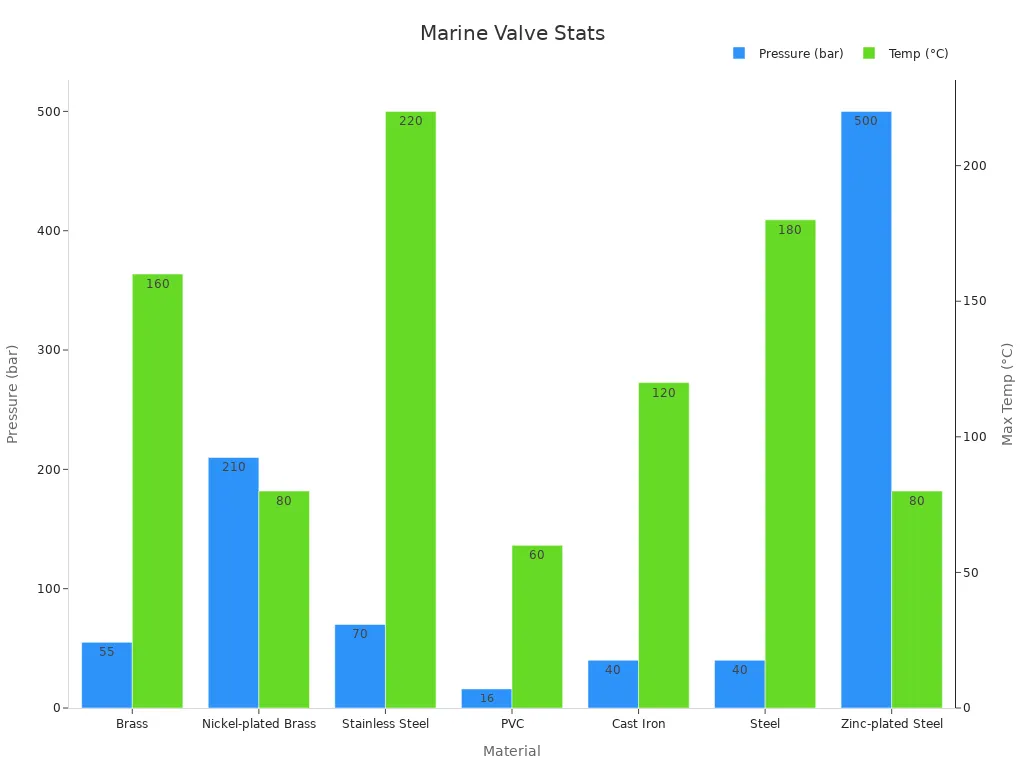

The chart below shows how different materials do with pressure and heat:

Stainless steel valves can take the most pressure and heat. This makes them great for hard jobs on boats. Bronze and composite valves are good at stopping rust and work well for most boats. Picking the right marine ball valve helps it last long and follow the rules.

UNIVALVE is well known in the marine world. It uses many materials and smart designs. The company makes marine ball valves from stainless steel, bronze, and special alloys. These valves can handle pressure from 10 to 100 bar. This means they work for easy and hard marine jobs. UNIVALVE has many certifications from groups like Lloyd’s Register, ABS, DNV/GL, BV, and CCS. These show the valves are safe and work well.

UNIVALVE tests its valves in tough ways. They check if the valves can handle fire and keep working. The valves meet API 607 and API 608 rules. This means they stay sealed in fire and work under high pressure and heat. Shipyards in South Korea, Singapore, and Greece use these valves. They trust them because they last long and do not rust. UNIVALVE also gives choices for how to open the valves. You can pick manual, electric, or pneumatic. This makes it easy to use in different marine systems.

Tip: UNIVALVE has many certifications. This helps shipbuilders and fleet owners follow rules everywhere.

Watts is trusted for its strong bronze in-line ball valves. These valves use good bronze that does not rust. They work in both fresh and salty water. The full-flow design lets water move easily. This keeps the system working well. Watts valves can take up to 55 bar of pressure. This makes them good for medium marine jobs.

Watts valves have UL, FM, and ISO certifications. This means they are safe and work well. The bronze makes them last long and easy to fix. Many boat owners like Watts because they are simple to put in and work well. These valves are best for water lines, bilge systems, and fuel lines.

Note: Watts bronze in-line ball valves are a good pick for boaters who want strong and affordable valves.

Cepex has a special Tru-Union ball valve. It is made from PVC or polypropylene. This makes it light and stops rust. The Tru-Union design lets you take out the valve body. You can clean or change it without touching the pipes. This saves time and money on repairs.

Cepex valves have ISO and WRAS certifications. This means they are safe for drinking water and marine use. They can handle up to 16 bar of pressure. This is good for low to medium jobs. Cepex valves are easy to put in and great for systems that need lots of care. Many marine workers like these for water treatment, ballast, and moving non-critical fluids.

Quick Tip: The Tru-Union design is great for systems that need cleaning or checks often.

Forespar Marelon ball valves are loved for their strong rust protection. Marelon is a special composite that never rusts, even in salty water. These valves are light, easy to use, and need little care.

Forespar Marelon valves have ABYC and ISO certifications. This means they pass hard safety and performance tests. They can take up to 10 bar of pressure. This fits most small and medium boats. Marelon is not metal, so it cannot get galvanic corrosion. Many sailors and boat builders use these for through-hull fittings, bilge systems, and other important jobs.

Note: Forespar Marelon valves are great for boaters who want valves that do not rust or need much care.

Apollo is different because it has strong features and many certifications. Its marine ball valves use top stainless steel. This gives them great rust protection and strength. Apollo valves have certifications from UPC, ANSI, and UL. These show the valves are safe and work well.

Apollo marine ball valves have high steam and gas pressure ratings. They can be used inside or outside. This makes them good for many marine and factory jobs. The valves come with guides to help users read markings and specs. Many marine engineers pick Apollo for high-pressure and high-heat systems.

Key features of Apollo marine ball valves:

Stainless steel makes them very strong

Certified for gas, steam, and water use

Easy-to-read markings and helpful guides

Pro Tip: Apollo’s many certifications and support make it a top choice for big ships and tough marine jobs.

Picking the right material is very important for marine ball valves. Stainless steel, bronze, and marelon are good choices. These materials do not rust in tough marine places. Stainless steel is very strong and works well in saltwater. Bronze is trusted and does not cost too much. It is often used for a high quality seacock. Marelon valves are light and do not get galvanic corrosion. This helps them last longer. These materials help the valve work well under pressure and last a long time, even when things get hard.

Key technical factors for material selection:

Good for high heat and pressure

Stops rust and damage

Works with marine fluids

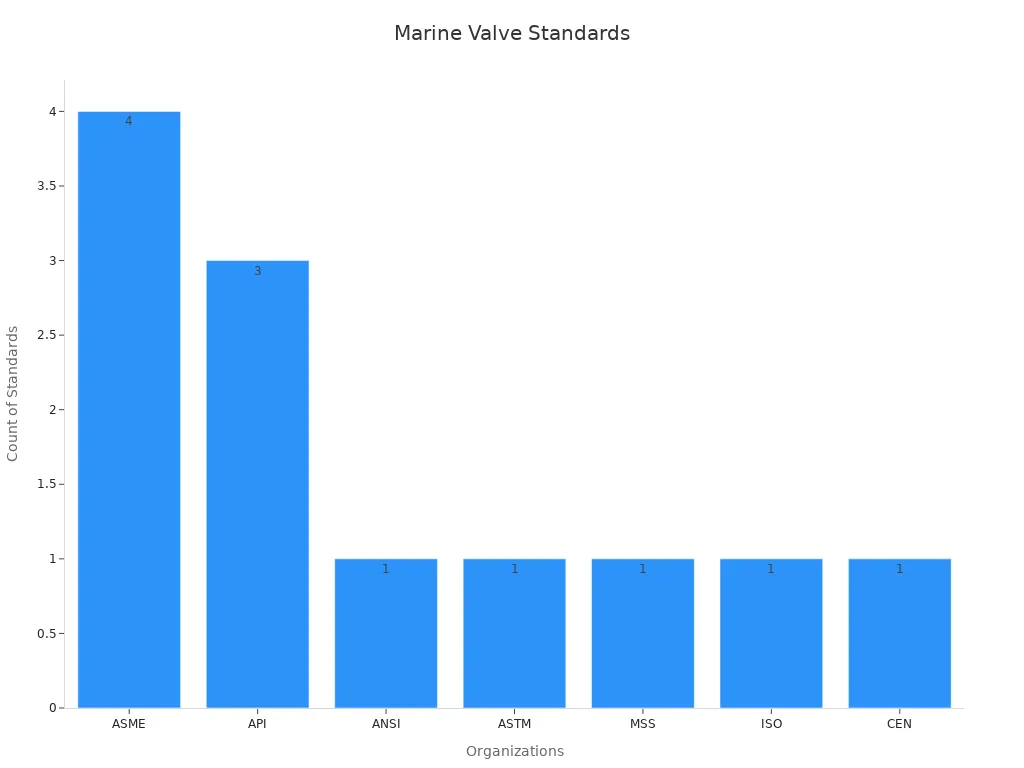

Certifications show that marine ball valves are safe and work well. Groups like ASME, API, ISO, and ASTM make the rules for size, pressure, and tests. Following these rules means the valve will work right on any ship.

Standards Organization | Relevant Standards and Scope |

|---|---|

ASME | F1020, B16.33, B16.34, B16.10 |

API | SPEC 6D, STD 598, STD 607 |

ISO | International sizing and compatibility |

ASTM | Material and testing standards |

Getting the right size and fit is very important. Buyers need to make sure the valve fits the pipe and system. International rules help make sure a high quality seacock fits and works on many boats.

Considerations for sizing:

Valve size

Pressure and flow needs

Right for the job

Easy setup and care help marine ball valves last longer. Many new valves have smart sensors for checking and fixing problems early. Having skilled people put in the valve and doing regular checks stops problems and saves money. Using real spare parts and keeping good records also help the valve work well for a long time.

Tip: Using smart checks and fixing problems early can help marine valves last longer and keep things safe.

Ball valves usually cost more than gate valves. But they last longer and seal better, so they are worth it. They turn off fast, which is important on boats. Even though they cost more at first, you save money because they need fewer repairs and last longer. Buyers should look at prices and see if there is a warranty to get the best deal.

Small boats need ball valves that are small and strong. These valves should not rust and need little care. Stainless steel and bronze are the best choices for these boats. Many owners pick socket weld ball valves with PTFE seats and blowout-proof stems. These parts help stop leaks and keep people safe. Most small boats use valves from 1" to 2" in size. These are used for thru hulls and water intake. Thru hulls and ball valves should follow JIS or API rules for safety. Many small boats also use intake strainers to keep junk out.

Feature | Details |

|---|---|

Material | Stainless steel, bronze |

Pressure Rating | 0.5 MPa to 6.0 MPa |

Standards Compliance | JIS, DIN, API, GB, ANSI |

Maintenance | Easy installation and low upkeep |

Application | Thru hull, water intake, bilge systems |

Tip: Make sure all thru hulls and ball valves are easy to reach. This helps you turn them off fast if there is an emergency.

Yachts and cruisers go in saltwater and need valves that last long. Marine-grade bronze ball valves are the top pick for below-waterline spots. These valves do not rust and can take high pressure. Matching threads right stops leaks and stress. Some yachts use Marelon valves for thru hulls, but bronze is stronger. Intake strainers keep junk and sea life out of the water system. Many yacht owners use mounting plates to hold valves in place without making more holes.

Marine-grade bronze has copper, tin, and silicone for extra strength.

Full flange bases and ball valves you can replace make fixing easier.

Good bronze valves work well and do not rust much, even after years.

Commercial ships need tough ball valves with strong certifications. Operators pick valves made from nickel aluminum bronze, copper nickel bronze, or titanium. These materials stop rust, stress, and sea life from causing problems. Most commercial ships use valves from 2" to 4" for thru hulls and fuel. Fire-safe and zero-leak valves are very important for safety. Valves must meet ABS, DNV, or Lloyd’s Register rules. Thru hulls and ball valves on these ships face hard jobs, so checking and fixing them often is needed.

Note: Certified valves help stop leaks and equipment problems. This keeps the crew and cargo safe.

Marine systems include fuel, ballast, cryogenic, and firefighting jobs. Each job needs special ball valve materials and designs. Stainless steel and special alloys are used for cryogenic and LNG systems. These systems have very cold and high-pressure needs. Bronze and composite valves are good for seawater and ballast. Thru hulls and ball valves must fit the system’s pressure and heat needs. Intake strainers are important to keep pumps and engines safe from junk. Operators should always pick valves with the right certifications for their system.

For saltwater: Use bronze or composite valves.

For fuel: Pick fire-safe, certified stainless steel or bronze valves.

For cryogenic: Use stainless steel or special alloy valves made for cold.

Marelon sea cocks are a favorite for boat owners who want easy care. The marelon ball valve uses a strong nylon material with glass inside. This makes it fight rust better than most metals. Marelon sea cocks do not get damaged by stray electricity or lightning like bronze ones. This makes them safer for boats. ASTM tests show marelon sea cocks can handle sun, scratches, and chemicals. They do not need bonding, so the crew has less work to do. Many people say these valves stay strong even if hit with tools. Using marine grease helps the valve turn easily and not get stuck. Marelon sea cocks are tough and need little care, so they are a good choice for long use.

Note: Marelon sea cocks stop galvanic corrosion, which is a big problem for metal valves in saltwater.

Marelon sea cocks are best where rust is a big worry but super strength is not needed. Boat makers use them for thru-hull fittings, bilge systems, and water lines. They are light, so putting them in is simple, especially on small boats. Marelon sea cocks work well in places that do not get hit much. Bronze and stainless steel valves are still used for high-pressure or risky spots. But marelon sea cocks are a good, easy-care choice for most boat plumbing. Checking and greasing them helps them work well, but they need less care than metal valves.

The best marine ball valves for 2025 are great because they stop rust, work in many temperatures, and seal tightly. The table below shows what each material is good for:

Material | Temp Range (°F) | Corrosion Resistance | Key Features |

|---|---|---|---|

N/A | Best for saltwater | Lasts long, safe for boats | |

Bronze | N/A | Good, easy to shape | Saves money, simple to put in |

Marelon/Nylon | N/A | No galvanic corrosion | Light, needs little care |

Brass | -50 to 450 | Better than plastic | Trustworthy, handles heat |

New valves have parts you can change and use strong seals like PTFE and EPDM. These things help stop leaks, make repairs easier, and keep people safe. Buyers should pick the right valve material and check for certifications that fit their boat. For help, talk to marine experts or look at what the makers suggest for the best place to get good valves.

A marine ball valve shuts off water very fast. It also seals tightly to stop leaks. Ball valves are safer and more reliable than gate valves. That is why many boaters pick them.

Experts say you should check marine ball valves twice a year. Regular checks help find rust, leaks, or damage early. This keeps your boat safe and working right.

Most experts say not to use plastic ball valves under the waterline. Metal or Marelon valves are stronger and safer for underwater use.

Certification | Organization |

|---|---|

LR | Lloyd’s Register |

ABS | American Bureau |

DNV/GL | DNV GL |

BV | Bureau Veritas |

Valves with these certifications follow strict marine safety rules.